A3MT-025/038-ASOKLO-G-D

A3MT-025/038-ASOKLO-G-D High-pressure Machine Tool Cooling Pump, designed for chip removal in CNC deep-hole machining and suitable as a replacement for KTS series products.Experience the use of 70-150bar high pressure. Whether it is high-pressure chip breaking,central water discharge or deep hole chip removal, the high-pressure screw pump will become your standard choice.High-pressure chip breaking is arigid demand for lathes and automated production lines, and is also a necessary condition for improving corporate competitiveness.

Description

A3MT-D series three screw pump is for metal processing machine tools to provide coolant (coolants, emulsions, oils,aqueous solutions), for high pressure applications, is a machine tool processing professional screw pump. The pressure of A3MT three-screw pump can reach 150bar, flow rate 1000L/min, for the machining work piece and tool precise washing, cooling, lubrication, chip breaking and chip removal, extend the tool service time, improve the precision, quality and efficiency of machined parts. It is an important product for precision machining of machine tools by manufacturers in various industries such as auto parts, aerospace and medical equipment.

Performance Data

Outlet Pressure: 10-150bar & 1-15Mpa

Flow Rate: 10-1000L/min & 1-60m³/h

Viscosity: 1-760mm/s& 1-760cSt

Temperature: Max.80℃& Max.176°F

| A3MT | 025/038 Flow Rate/Q”L/min” Shaft Power/P”kW” Speed(rpm)=2900rpm |

|||||||||||||||

| Outlet Pressure (bar) |

10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 110 | 120 | 130 | 140 | 150 | |

| Viscosity 1cSt |

Q | 29.7 | 28.7 | 27.7 | 26.8 | 25.9 | 25.0 | 24.2 | 23.4 | 22.7 | 22.0 | 21.4 | 20.8 | 20.2 | 19.7 | 19.3 |

| P | 0.7 | 1.3 | 1.9 | 2.5 | 3.1 | 3.7 | 4.3 | 4.9 | 5.5 | 6.1 | 6.7 | 7.4 | 7.9 | 8.5 | 9.1 | |

| Viscosity 20cSt |

Q | 30.4 | 29.8 | 29.3 | 28.9 | 28.4 | 28.0 | 27.6 | 27.2 | 26.8 | 26.5 | 26.2 | 25.9 | 25.6 | 25.4 | 25.1 |

| P | 0.7 | 1.3 | 1.9 | 2.5 | 3.1 | 3.7 | 4.3 | 4.9 | 5.5 | 6.1 | 6.7 | 7.4 | 7.9 | 8.5 | 9.1 | |

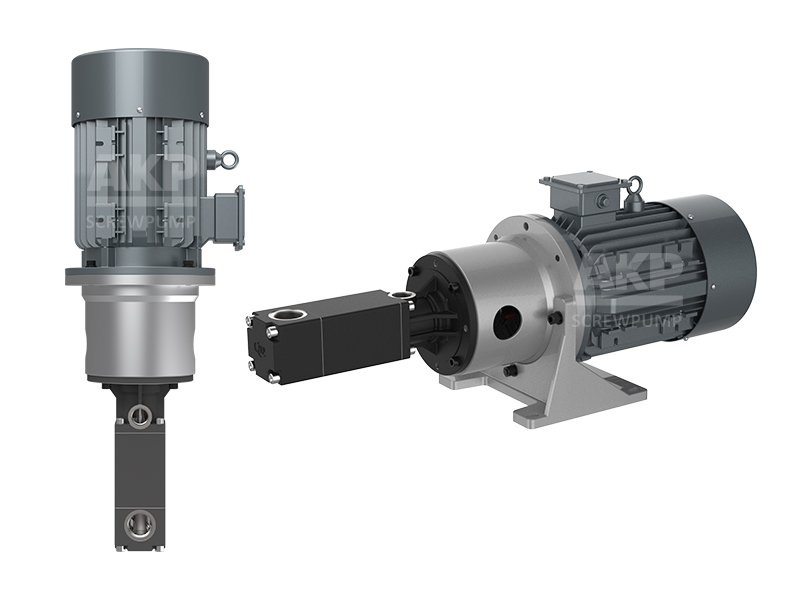

Mounting: Vertical ( in-tank/top mounting)or Horizontal (foot mounting)

Mounting: Vertical ( in-tank/top mounting)or Horizontal (foot mounting)

Material: Composite ceramic bushing is standard

Valve: Can be Selected

Product Advantages

1.A3MT screw pump changes the traditional high pressure oil balancing technology, the use of active screw and driven screw axial force low pressure area mechanical balancing device, so that the screw force balance uniform and stable, screw does not deform, stable and reliable operation, low noise no pulsation

2.Labyrinth seal design, wear-resistant piston sleeve structure, can effectively reduce the pressure of the seal chamber, reduce the pressure to reach the mechanical seal, to ensure that the pressure of the seal chamber within the design pressure

3.A3MT screw adopts special hardening to strengthen the hardness, tensile strength, finish and precision of the screw, which can be well established in the process of conveying medium, and the establishment of the oil film is the basis of ensuring the operation life of the pump

4.A3MT screw pump, standard ceramic lining, higher wear resistance

5.High wear-resistant mechanical seal, special rubber seal, double seal design, anti-fouling protection

SELECTION GUIDE

To provide a more suitable pump, we need to understand as much detailed information as possible. You can request the working condition survey form from me. If you are replacing an existing pump, you can provide me with the original product model or nameplate.

Why choose us

1.The initial cost is low, we are a factory, all products are mass production, whether you need one or one hundred sets, we provide the factory price, purchasing here can reduce your procurement cost

2.High energy efficiency, we are a professional screw pump manufacturer, with strict manufacturing standards, can provide different seal forms, reduce the internal leakage of the pump, improve the efficiency of pumping

3.Low maintenance cost, when the screw or bushing wear, can not meet the pumping requirements, we can provide pump core components, easy to replace, compared to re-purchase a pump, the cost is lower

4.Short downtime, when your site failure, we can provide remote support, professional engineers and you to communicate, troubleshoot the site fault, you can use the shortest time to assist you to resume production

5.Long service life, because we have professional and senior technical application engineers to provide you with the correct product selection, scientific product selection and correct necessary working conditions to communicate in order to select the cost-effective three screw pump product configuration, to high life operation and work, for your host equipment to provide scientific and good protection and maintenance.

Instructions for use

Before starting for the first time, please fill the lubricating medium oil to ensure that a good oil film is formed on the surface of the screw pair and spiral groove. If you want to make the service life of the screw pump longer, the following points are very important

1.It is strictly forbidden to tighten the import and export connection flange, so that the base pump body deformation and displacement, damage the inherent accuracy of the pump

2.When configuring the pipeline, it is strictly forbidden to damage the coaxial tightness of the pump and the motor to ensure the reliable sealing of the import and export pipeline connection.

3.During installation, the rubber plug of the inlet and outlet must be removed, and any impurities and welding slag must not enter the pump chamber.

4.It is strictly prohibited to operate or use water media without media. Or use other media to clean the pump.

5.Long unused and before the first start, the pump cavity must be filled with the use of media.

6.The pipe diameter configuration must be consistent with the pump diameter. The inlet and outlet pipe valves must be opened when starting.

7.It is strictly prohibited to use pressure exceeding the rated working pressure of the pump.

8.Do not adjust the safety valve adjusting bolts, which have been adjusted before delivery. The safety valve cannot be used as an relief valve

9.It is strictly prohibited to disassemble the pump parts without the written permission of the manufacturer

10.Screw pump is a positive displacement quantitative pump, its working pressure depends on the system load.

Reviews

There are no reviews yet.