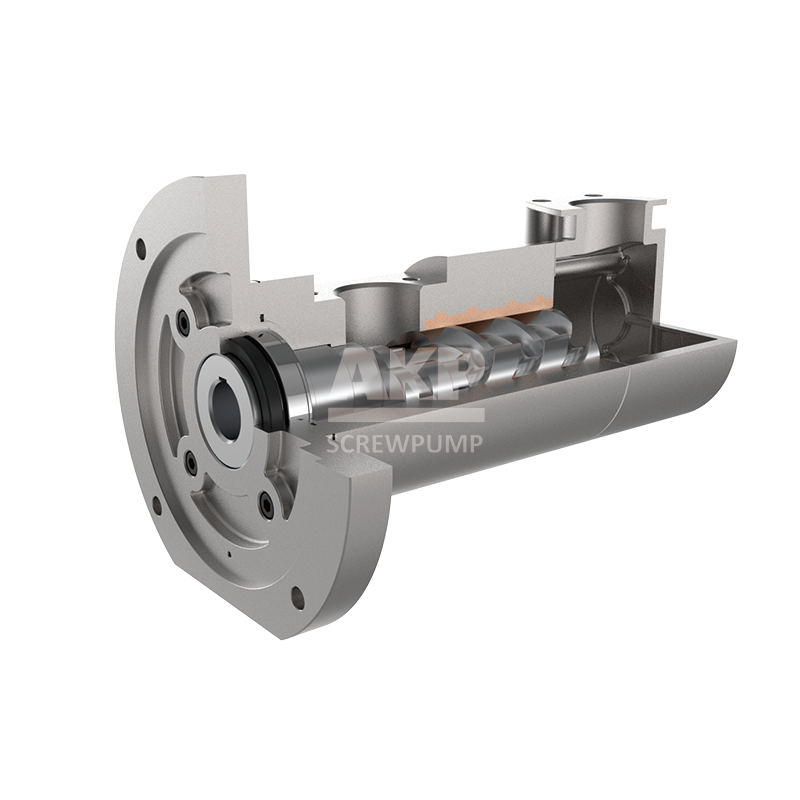

A3NK Triple Screw Pump

A3NK and A3NO are products of the same type. Their difference lies in that the A3NK series is a concave-shaft pump, which connects directly to the motor without the need for a coupling.

Description

A3NK Series Three-Screw Pump is a self-priming volumetric quantitative pump Suitable for use under low and medium pressure (40bar), suitable for conveying non-wear and non-corrosive, with a certain viscosity and lubricity of fluids, in diesel engines, turbines, compressors, steam turbines, gear reduction machines and gear boxes as lubrication pumps; Compressors, generators and other equipment as sealing oil pump, control oil pump; Forging presses, machine tools, injection molding machines, propellers, hydraulic winches and elevator lifts as hydraulic oil pumps…

Performance Data

Outlet Pressure: 10-40bar & 1-4Mpa

Flow Rate: 10-3200L/min & 1-192m³/h

Viscosity: 1-2500mm/s& 1-2500cSt

Temperature: Max.300℃& Max.572°F

Mounting: Horizontal (bracket) or Vertical (submerged)

Protection: Normal(nopressure relief valve) or RP valve (external variable valve)

Sealing: Mechanical Seal, Lip oil seal, Magnetic Drive Without Any leakage

Application

1.Power generation industry:As lubricating oil pump and cooling oil pump, perform lubrication cycle cooling service for turbine, blower, diesel engine, compressor and other equipment; Seal oil pump and control oil pump for generator.

2.Mining machinery:For mining machinery and equipment lubrication, vertical mill circulating lubricating oil pump, ball mill gear lubricating oil pump, coal mill thin oil lubricating pump, cement mill thin oil lubricating pump

3.Hydraulic technology:In forging press, injection molding machine, discharge device, elevator lift, Marine propeller, hydraulic winch and other equipment, as a hydraulic pump to provide power hydraulic services.

Product Advantages

1.A3NK screw pump changes the traditional high pressure oil balancing technology, the use of active screw and driven screw axial force low pressure area mechanical balancing device, so that the screw force balance uniform and stable, screw does not deform, stable and reliable operation, low noise no pulsation

2.The screw is the core of the pump. The A3NK screw is made using a special processing technique that enhances the screw’s hardness, tensile strength, smoothness, and precision. During the transportation of media, it effectively establishes an oil film, which is fundamental to ensuring the pump’s operational lifespan.

3.A3NK screw pump is a commonly used three-screw pump in industry, which is very suitable for installation in small Spaces, at the same time, we can also lift For the concave shaft version, it is smaller in size

4.A3NK screw pump, can provide a variety of oil inlet configuration to choose to meet the needs of different working conditions.

SELECTION GUIDE

To provide a more suitable pump, we need to understand as much detailed information as possible. You can request the working condition survey form from me. If you are replacing an existing pump, you can provide me with the original product model or nameplate.

Why choose us

1.The initial cost is low, we are a factory, all products are mass production, whether you need one or one hundred sets, we provide the factory price, purchasing here can reduce your procurement cost

2.High energy efficiency, we are a professional screw pump manufacturer, with strict manufacturing standards, can provide different seal forms, reduce the internal leakage of the pump, improve the efficiency of pumping

3.Low maintenance cost, when the screw or bushing wear, can not meet the pumping requirements, we can provide pump core components, easy to replace, compared to re-purchase a pump, the cost is lower

4.Short downtime, when your site failure, we can provide remote support, professional engineers and you to communicate, troubleshoot the site fault, you can use the shortest time to assist you to resume production

5.Long service life, because we have professional and senior technical application engineers to provide you with the correct product selection, scientific product selection and correct necessary working conditions to communicate in order to select the cost-effective three screw pump product configuration, to high life operation and work, for your host equipment to provide scientific and good protection and maintenance.

Instructions for use

Before starting for the first time, please fill the lubricating medium oil to ensure that a good oil film is formed on the surface of the screw pair and spiral groove. If you want to make the service life of the screw pump longer, the following points are very important

1.It is strictly forbidden to tighten the import and export connection flange, so that the base pump body deformation and displacement, damage the inherent accuracy of the pump

2.When configuring the pipeline, it is strictly forbidden to damage the coaxial tightness of the pump and the motor to ensure the reliable sealing of the import and export pipeline connection.

3.During installation, the rubber plug of the inlet and outlet must be removed, and any impurities and welding slag must not enter the pump chamber.

4.It is strictly prohibited to operate or use water media without media. Or use other media to clean the pump.

5.Long unused and before the first start, the pump cavity must be filled with the use of media.

6.The pipe diameter configuration must be consistent with the pump diameter. The inlet and outlet pipe valves must be opened when starting.

7.It is strictly prohibited to use pressure exceeding the rated working pressure of the pump.

8.Do not adjust the safety valve adjusting bolts, which have been adjusted before delivery. The safety valve cannot be used as an relief valve

9.It is strictly prohibited to disassemble the pump parts without the written permission of the manufacturer

10.Screw pump is a positive displacement quantitative pump, its working pressure depends on the system load.

Reviews

There are no reviews yet.