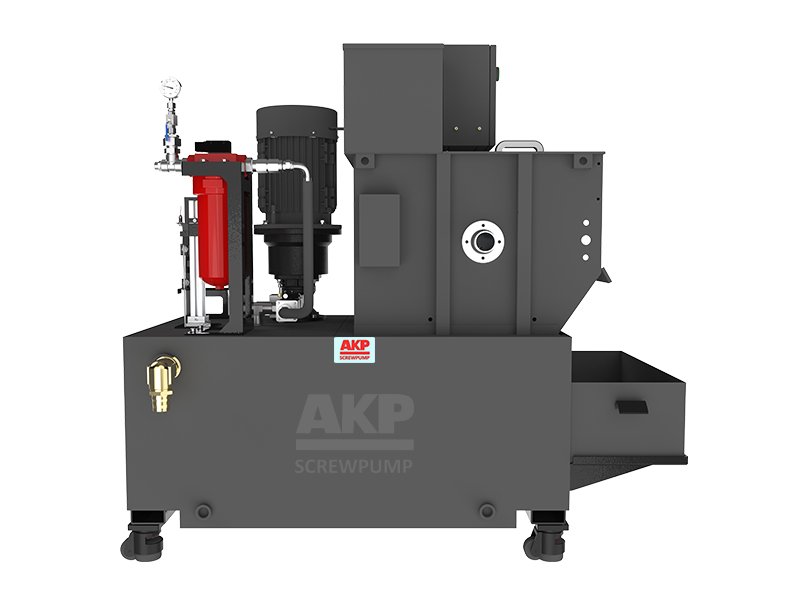

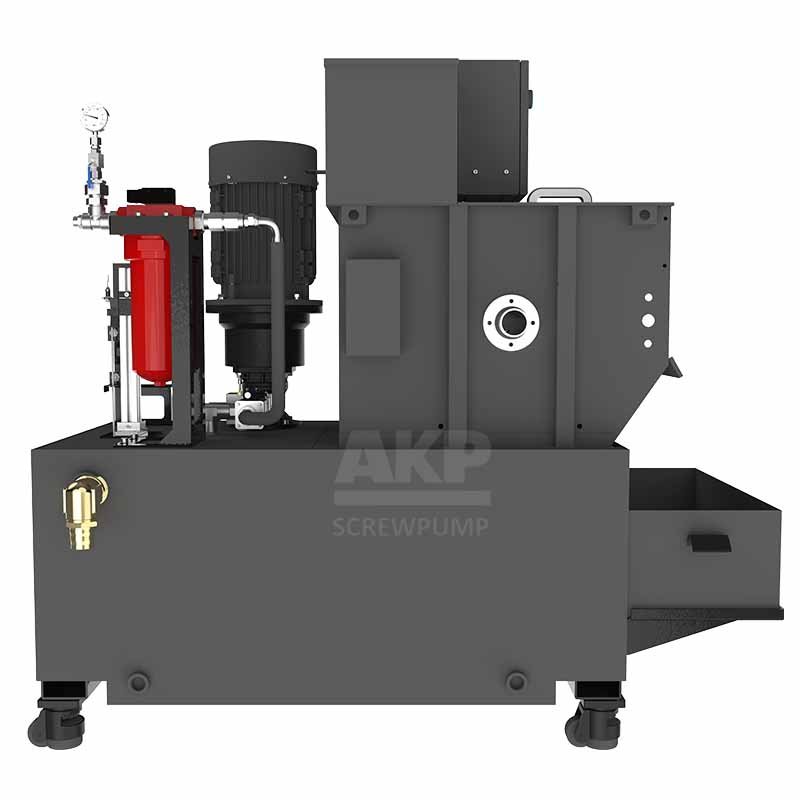

A3SS-XT15 High Pressure Coolant&Filtration Systems

Hydrostatic Drum Filter System

Description

Hydrostatic Drum Filter System is composed of a liguid tank, a dirt collecting tank, filter paper, a reducer, atransmission mechanism, a signal transmission mechanism, a liquid supply pump, etc. During operation, the filter paper is used to separate the fine chips and impurities in the coolant. The labyrinth design is equipped with multiple filter screens for easy cleaning. The high-pressure screw pump and the integrated chip removal core components have the advantages of high pressure, large flow, and high performance. In addition, there are three-stage filters and micronlevel filtration, which can effectively protect the machine tool spindle and rotary joint.

Typical application scenario

Suitable for heavy chipping conditions, vortex separator with bag filter, vertical pump assembly skid-mounted structure. Compatible with vertical/horizontal machining centers, turning and miling production lines, and suitable for machining steel.aluminum,stainless steel.etc.

Main technical parameter and selection

- Tank Volume 400L

- Bulk Volume 1580×700×1360mm

- Screw Pump Installation Method Vertical Type

- Lift Pump Parameter Flow 4m³/h Lift 30m

- Pressure Regulator Type Coaxial Valve

- Filter Combination Vortex Separator+Drum Filter+High Pressure Line Filter

- Filtration Accuracy 15-60μm

- Control Mode Terminal Box / AKP Module / Integrated PLC

Reviews

There are no reviews yet.