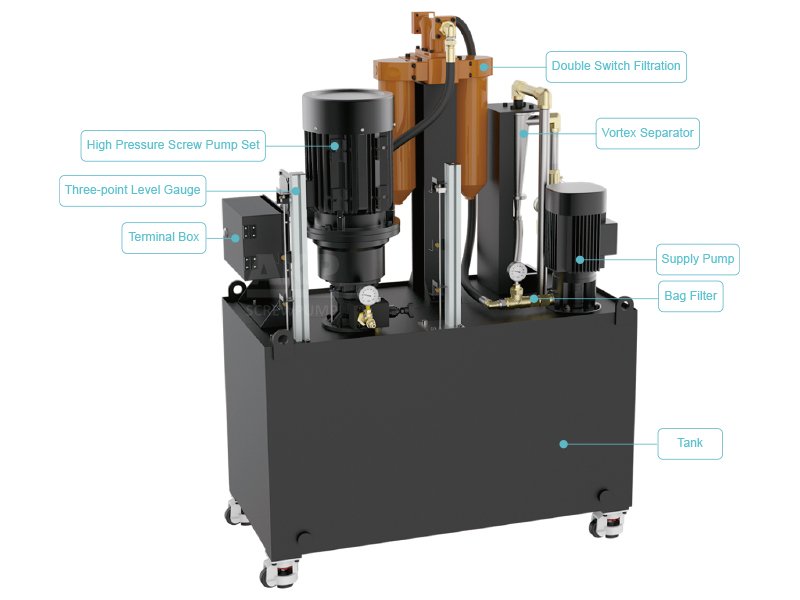

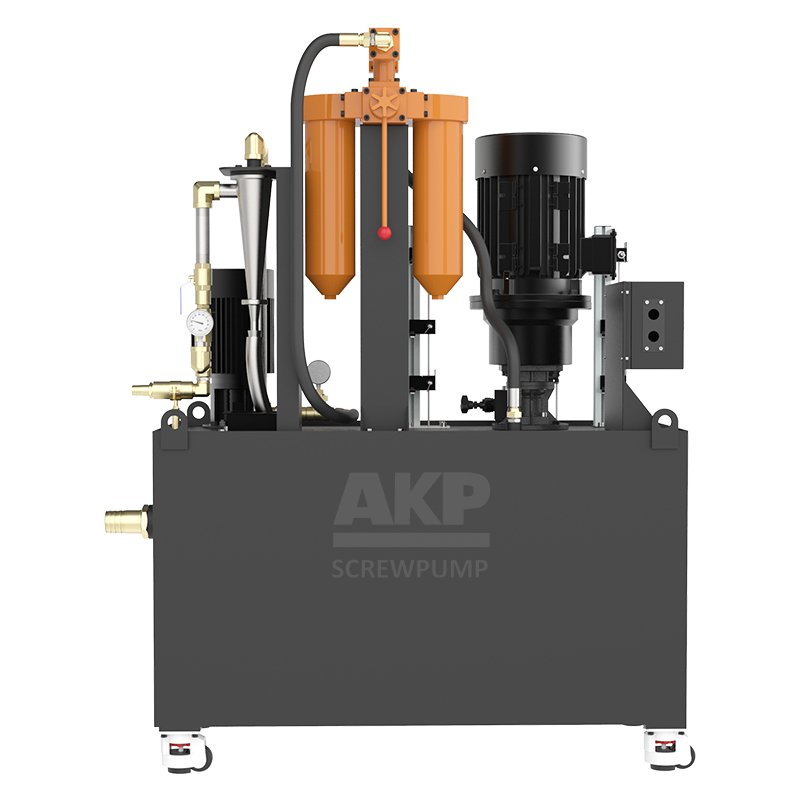

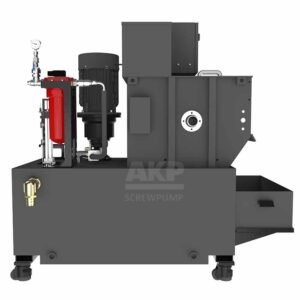

A3SS-XT7 High Pressure Coolant&Filtration Systems

A3SS-XT7 Double Switch Filter High Pressure Coolant System

Description

A3SS-XT7 Double Switch Filter High Pressure Coolant System double cylinder filter can be used for 24 hours non-stop working conditions,under normal working conditions for single cylinder filter work, manually switch the filter mode when replacing the filter element, when a filter alarm, switch to another clean filter cylinder work, in principle can be realized online switch to replace dirty filter cylinder. The design method of the main and secondary water tanks, the liquid slag recovery device,and the lifting pump of the secondary water tanks are adopted. The filtration method of the first stage is vortex filtration.After the filtration of the secondary water tank is completed, the lift pump transmits the coolant to the double switch filter to the main water tank, which effectively ensures that the work is not shut down for 24 hours under harsh working conditions.

Typical application scenario

Suitable for heavy chip cutting conditions, with built-in double water tank filtration structure.Compatible with vertical/horizontal machining centers, turning and miling production lines, five-axis linkage machine tools, and suitable for processing steel,aluminum, and stainless steel parts.

Main technical parameter and selection

- Tank Volume 1500×600×500mm(450L)

- Bulk Volume 1500×600×1400mm

- Screw Pump Installation Method Vertical Type

- Lift Pump Parameter Flow 4m³/h Lift 30m

- Pressure Regulator Type Two-position Three-way Valve / Plate Pressure Regulator / Proportional Valve

- Filter Combination Vortex Separator+Double Switch Filtration

- Filtration Accuracy 25μm +10μm

- Control Mode Terminal Box+Machine Control

Reviews

There are no reviews yet.